-

MenuBack

-

Home

Home

-

Products

- Certification

-

About us

-

FAQ

-

Contact

-

NEW Product

NEW Product

-

Free Shipping

Free Shipping

Filter By

Single/Dual Shaft

Single/Dual Shaft

Phase Resistance

Phase Resistance

Active filters

It’s incredible how much power can be packed into something the size of a postage stamp. The NEMA 8 stepper motor is one of the smallest in its class, yet it delivers unparalleled precision and control in some of the most demanding environments, from laboratory equipment to compact robotics.

Thinking of using a stepper motor, but not sure which size is best for your project? Or maybe you're wondering whether something so small can actually do the job?

The truth is that choosing the right motor isn’t just about torque or technical specifications — it’s about selecting the appropriate tool for the task at hand. If your design calls for tight spaces, low power and precise movement, NEMA 8 might be exactly what you need.

In this article, we’ll explain what NEMA 8 really means, demonstrate how it performs in real-world applications, and outline why it’s a popular choice for hobbyists and professionals alike. By the time you've finished reading, you'll know exactly where this tiny motor fits — and why it could be the best choice for your next project.

Understanding the NEMA 8 frame size

So, what exactly is a NEMA 8 stepper motor? Let’s break it down together. If you’re new to stepper motors or just need a refresher, this section will walk you through the basics of the NEMA 8 frame: what it means, why it matters and how it is used in practice.

This isn't about bombarding you with technical specifications. It's about equipping you with the knowledge to confidently identify when this motor is suitable for your project and what to expect from it.

What 'NEMA 8' actually means

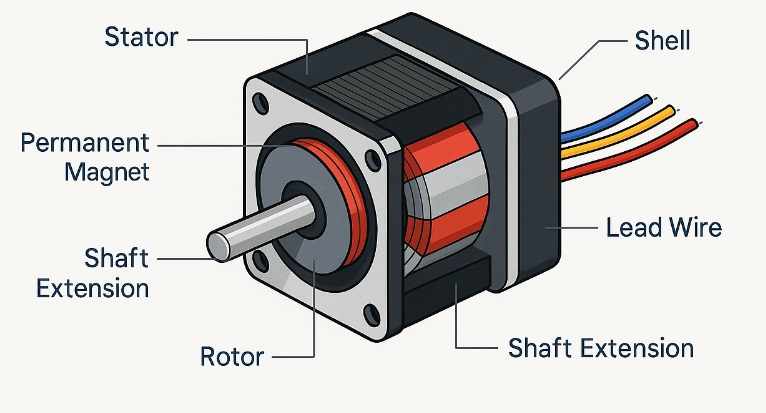

Let's start with the word 'NEMA'. It stands for the National Electrical Manufacturers Association. They set the standards for motor dimensions, meaning parts from different manufacturers can work together. So when you buy a motor labelled 'NEMA 8', you know exactly what size it's supposed to be — no surprises.

The '8' refers to the size of the motor's faceplate, which is 0.8 inches square (about 20 millimetres). This number has nothing to do with power or performance, only the standardised mounting face. This information is useful when trying to choose a motor that fits into a tight mechanical design or enclosure.

In short, NEMA 8 is all about size. It doesn't define torque, speed or wiring, just the frame. However, don't underestimate the impact that frame size can have on your entire design strategy.

Specific dimensions of NEMA 8 motors and how they compare to other sizes

NEMA 8 stepper motors typically have a faceplate measuring 20 mm x 20 mm, making them smaller than the more common NEMA 17 motors, which measure 43.2 mm square. Their body length can vary, often from 30 mm to 60 mm depending on the torque rating and whether an encoder or gearhead is included.

Shaft diameters usually fall within the 3 mm range, and the step angle tends to be 1.8°, translating to 200 steps per revolution. This level of precision is more than adequate for most compact motion control tasks.

When space is limited — think handheld devices, compact robots or small laboratory equipment — these tiny motors really come into their own. Compared to their larger counterparts, they offer impressive control in a much smaller footprint.

Why Size Influences Design Decisions

Now here’s the part most folks overlook: motor size isn’t just about fitting into a smaller space. It affects your overall system design, from the housing and heat management to cable routing.

Opting for a NEMA 8 motor opens up possibilities where larger motors simply won't fit. However, the trade-off is lower torque, so it’s important to consider your application carefully. If your setup requires micro-precision rather than brute force, the NEMA 8 motor could be the perfect solution.

In short, size isn’t everything, but in tight spaces, it can be the deciding factor in whether your design works or not.

Key specifications and common features

All right, let's talk specs — but in human terms.

Typical holding torque range:

Holding torque is essentially the amount of force that the motor can withstand when it is not rotating. For NEMA 8 motors, this usually ranges from 4 to 10 N·cm (Newton-centimetres). This is not a high torque rating, but it is sufficient for light loads, precise positioning and low-resistance mechanical systems.

Bear in mind that torque varies depending on the motor’s body length and the current supplied. So even within the NEMA 8 category, there is some flexibility for matching torque to your project.

Shaft diameter, step angle, and body length explained in simple terms

Most NEMA 8 motors have a 3 mm shaft, though this can vary slightly. The step angle, or how far the motor rotates per pulse, is typically 1.8 degrees, meaning it takes 200 full steps for one complete turn. If your project requires greater precision, some models offer finer resolutions with microstepping.

Shorter models are ideal for tight spaces, but produce less torque. Longer models can exert greater force, but they may add weight and complexity to your setup.

Voltage and Current Ratings in Plain Language

These motors usually run on 3V to 5V, with current ratings of between 0.3A and 1A per phase depending on the design. This is ideal for battery-powered devices, microcontroller-based systems or anything that cannot handle high power.

However, you should always check your driver's specifications to avoid undervolting or overheating. A mismatch can affect performance or shorten motor life.

Ideal operating conditions

Even though NEMA 8 motors are compact, they still have specific requirements regarding working conditions.

Common voltage and current settings for typical applications

For most applications, 5 V at 0.5 A per phase is a suitable setting. This provides a good balance between torque and heat. However, if you're pushing the motor harder, for example with a heavy load or quick acceleration, you might need a more robust driver or a heat sink.

Just because a motor can run at lower voltages does not mean that it should. Always aim for stable, clean power — your motor will thank you with a longer life and better performance.

Heat Considerations and What to Look Out For

Small motors can heat up quickly. Since NEMA 8 motors often run in tight spaces, airflow can be limited. That's why it's sensible to monitor the motor's temperature during extended use. If the motor is too hot to touch, it is too hot for reliable long-term use.

Simple steps such as adding a fan, using intermittent duty cycles or mounting the motor to a metal frame can help to dissipate heat safely.

Matching NEMA 8 with compatible drivers and controllers is also important.

Not all drivers are suitable for NEMA 8 motors; you’ll want one that supports low current ratings and microstepping for precision. Popular options include the A4988, the DRV8834 and the TMC2208, all of which are well-suited to these smaller motors.

Also, double-check your controller’s output. If you’re using something like an Arduino or Raspberry Pi, ensure your driver board acts as an interface; it will handle the current load, meaning your microcontroller won't have to.

Looking for a motor that’s small, smart, and efficient? NEMA 8 might be the answer — as long as you understand its capabilities and limitations. Next, we’ll examine how these motors are used in real-world projects and explore the reasons behind their popularity in some advanced applications.

By now, you should have a good understanding of what defines the NEMA 8 stepper motor: its compact frame, modest torque and ideal operating conditions. We’ve also covered how its size and specifications influence design decisions, especially when space is limited and precision is paramount. Now it’s time to look at where this little workhorse earns its keep.

The beauty of the NEMA 8 lies in its versatility. While it's not designed to move mountains, it excels in spaces where larger motors simply won't fit or would be excessive. From high-tech laboratories to homemade gadgets, this motor can be found in some pretty ingenious setups.

Typical applications and use cases

Perfect for compact spaces!

If you’re working with limited space, the NEMA 8 is often the best option. It’s designed for situations where every millimetre counts, such as with wrist-sized robots or palm-sized equipment. Its 20 mm square frame makes it easy to fit into tight enclosures without sacrificing precision or control.

NEMA 8 is the perfect match for small-scale robotics. Whether you need a robotic arm for assembling tiny parts or a mobile robot that must be feather-light and nimble, the motor provides just enough torque to get the job done while keeping the design clean and efficient. Its lightweight nature also means that it won't affect your centre of gravity or require heavy-duty mounting systems.

Medical devices are another area where the NEMA 8 thrives. Imagine a portable blood analyser or a compact infusion pump — these machines need to be accurate, reliable and quiet. The NEMA 8 fits the bill perfectly. It enables precise movement without adding bulk or noise to the device, which is essential in a clinical setting.

In laboratory automation, it is often used in small actuators or sample-handling systems. The motor’s low profile and quiet operation help it to blend into environments where precision and subtlety are more important than brute strength. It is also popular in micro-machines, where mechanical components need to be extremely precise.

3D printers and DIY projects

Now, let's talk about the world of makers. If you’re into 3D printing or building your own gadgets, the NEMA 8 motor is that reliable, low-maintenance friend who always shows up to help — and is surprisingly strong for its size.

In compact or custom 3D printers, NEMA 8 motors are often used to drive extruders or move lightweight components along the X or Y axis. Their precision helps to produce smoother prints, and their small size leaves room for other upgrades or design tweaks. For those trying to build a portable or mini 3D printer, this motor is the obvious choice.

Hobbyists love NEMA 8 motors for one simple reason: flexibility. It’s small enough to mount just about anywhere yet powerful enough for tasks such as operating camera sliders, laser engravers or motorised turntables for product photography. The motor's consistent performance and standard step angle (typically 1.8 degrees) facilitate integration with standard driver boards and microcontrollers.

Imagine building a motorised microscope stage for under £100 — or an autofocus rig for your Raspberry Pi camera. These are exactly the types of projects where the NEMA 8 motor excels. It provides the movement you need without adding bulk or complexity to your design.

Lightweight Automation Systems

NEMA 8 isn’t just for hobbyists and scientists — it’s also finding its way into industrial settings, particularly where lightweight automation is key.

Take micro conveyor systems, for example. These are often used in small-scale packaging, electronics inspection or part sorting. When heavy loads aren't being moved, a NEMA 8 motor can offer the perfect balance of control and size. It’s also energy-efficient, helping to reduce system-wide power consumption.

Micro grippers — think robotic fingers that gently pick up small items — are another great match. These systems often require a precise yet gentle grip, so a bulky motor would be counterproductive. With a NEMA 8 motor, you get subtle control in a compact design that won't overwhelm the mechanism.

In inspection tools, particularly those used for PCB testing or sensor alignment, these motors facilitate precise adjustments and component positioning for close-range scanning. Since these systems often require rapid yet accurate movement, the motor’s small size and smooth step transitions are exactly what engineers are looking for.

Of course, there are trade-offs. Opting for a NEMA 8 means accepting lower torque, so it is not suitable for lifting or rotating heavy parts. If your automation system needs to move a large load or operate in a high-friction environment, you will require a NEMA 11 or NEMA 17 motor. However, for many lightweight applications, the NEMA 8 strikes the perfect balance between performance and practicality.

In short, the NEMA 8 may be small, but its range of uses is extensive. From precise laboratory instruments to portable 3D printers and micro-automation tools, it fills a niche that larger motors simply cannot. In the next section, we’ll explore how to choose the right NEMA 8 motor for your needs and what to consider while shopping for one.

Choosing the Right NEMA 8 Motor

Choosing the Right NEMA 8 Motor

As we've already seen, the NEMA 8 motor thrives in tiny spaces, with precise movement and lightweight tasks. From compact robotics to medical devices and 3D printing setups, it's clear that this motor is essential in the right scenarios. However, knowing where to use it is only half the battle. Now, let’s talk about how to choose the right NEMA 8 model for your specific application.

Selecting an unsuitable motor, even within the NEMA 8 category, can result in frustrating setbacks. Insufficient torque, incompatible wiring or the wrong shaft type can jeopardise your entire build. This section is your guide to getting it right from the outset.

Things to Consider Before Buying

Before clicking 'Add to Cart', take a step back and consider your project's real needs. The NEMA 8 family isn’t huge, but there’s still a good variety of specifications and features to consider.

Start by asking yourself:

- What kind of load will this motor need to move?

- How much torque do I actually need?

- Will it be running continuously or in short bursts?

- What kind of space am I working with? Are there tight corners or shallow enclosures?

- Which controller or driver am I using?

If you are designing a portable or battery-powered device, current consumption is important. If the motor will run for long periods, heat management becomes a priority. If it’s part of a mechanical assembly, the mounting style and shaft type can determine whether the installation is successful.

Don't just go by what's in stock or what seems cheapest. A few minutes of planning can save hours of tweaking later on.

The importance of torque-to-size ratio and mounting style

Here’s a simple truth: a NEMA 8 won't provide the same torque as a NEMA 17. But that’s OK, because that's not its purpose. The goal is to balance performance with footprint, and that’s where the torque-to-size ratio comes in.

Most NEMA 8 motors have a holding torque of between 4 and 10 N·cm, depending on body length and coil configuration. A longer body usually means more torque, but you’ll need to check whether your design can accommodate the extra length. Look for motors that offer enough torque with a safety margin – don't choose something that just meets your needs at 100%.

Mounting style also matters more than people realise. NEMA 8 motors use a standard 20 mm square faceplate, but the mounting holes and shaft alignment may differ slightly. If you are upgrading or replacing an existing motor, double-check your measurements before committing.

Popular models and variants

Even within this small category, there are quite a few options to choose from. You’ll see part numbers such as 20HS08-0404S or 17HD0803-22B. While these may appear confusing at first, they actually provide a lot of information.

Let's break them down:

- The '20' or '08' often refers to the body size (20 mm = NEMA 8).

- 'HS' typically means 'Hybrid Stepper', which is the most common type.

- The following numbers may represent length, current rating or torque, depending on the manufacturer.

It’s worth consulting the datasheet before making a purchase, as different brands use slightly different naming conventions and small specifications can have a significant impact on performance.

Differences between single-shaft and dual-shaft designs

One often-overlooked detail is whether the motor has a shaft on one end or both ends. A single-shaft motor is ideal for direct coupling to gears or pulleys, whereas a dual-shaft version allows you to add an encoder or manual knob at the back.

If your setup requires position feedback or you want the option to add it later, a dual-shaft motor provides that flexibility without the need to modify the body. Just make sure your enclosure has room for the extra shaft.

Encoder Options and Extended Features

Encoders aren’t always included with NEMA 8 motors, but they’re becoming more common in high-precision applications. You will usually find incremental rotary encoders that attach to the back shaft and provide digital feedback for closed-loop control.

For most hobby and light-duty setups, encoders aren’t essential. However, if you are working on closed-loop motion control for something like a surgical tool or a precision dispenser, they can significantly improve accuracy and reduce error. Bear in mind that adding an encoder will increase both the cost and the space requirements, so ensure that it fits your design.

Other extended features might include custom shaft lengths, geared variants or pre-wired connectors for plug-and-play integration. These can simplify assembly and reduce the need for troubleshooting later on.

Wiring and connector types

Now, let's discuss wiring, because there's nothing worse than a motor that won't communicate with your driver.

Most NEMA 8 stepper motors have a 4-wire configuration, which is ideal for bipolar stepper drivers. Some may offer 6-wire or 8-wire versions, but these are more common in larger motors. Unless you have a specific reason to use the others, stick with 4-wire — they’re simpler to work with and fully compatible with most microstepping drivers.

Miniature Connectors Used and Compatibility Tips

Given the small size of these motors, the wires are usually thin and short and are often terminated in JST-PH or Molex Micro-Fit connectors. These connectors are compact and space-saving, but they are not always easy to solder or modify.

If you’re building a custom board or cable, check the pinout carefully, as there is no universal standard. Mismatched wiring can damage a driver or cause the motor to behave erratically. When in doubt, test continuity across coils and refer to the manufacturer’s datasheet.

Some suppliers offer models with pre-crimped cables, which can save time and reduce the risk of wiring errors. This is worth paying a few extra dollars for if you’re doing multiple units or value reliability over DIY flexibility.

In short, choosing the right NEMA 8 motor requires some initial research. Consider your application, prioritise what is important to you, and select a model that balances precision, torque, and simplicity. In the next section, we’ll compare NEMA 8 with other popular sizes to help you decide whether to go small or scale up.

Conclusion:

The NEMA 8 stepper motor may be small, but it plays a significant role in designs where space, precision and control are paramount.

In this guide, we have covered what the NEMA 8 is, how its compact size influences design decisions and its strengths, from robotics and medical devices to 3D printing and lightweight automation.

Whether you're working on a DIY project or building a specialised piece of equipment, the NEMA 8 offers a smart, reliable solution when larger motors simply won't fit. Its unique balance of precision and efficiency makes it a favourite among engineers, makers and designers who want to keep things clean and compact without compromising on performance.

Now that you understand what makes the NEMA 8 special, take the next step: match it with your project's requirements, compare the specifications of products from trusted suppliers, or even test one out in a prototype. The more hands-on you get, the clearer its value becomes.

Remember – great design often starts with the right details. When you need a motor that delivers control in a small package, the NEMA 8 could be the detail that brings your build to life.