-

MenuBack

-

Home

Home

-

Products

- Certification

-

About us

-

FAQ

-

Contact

-

NEW Product

NEW Product

-

Free Shipping

Free Shipping

Filter By

Holding Torque

Holding Torque

Shaft Length

Shaft Length

Shaft Type

Shaft Type

Inductance

Inductance

Phase Resistance

Phase Resistance

Introduction

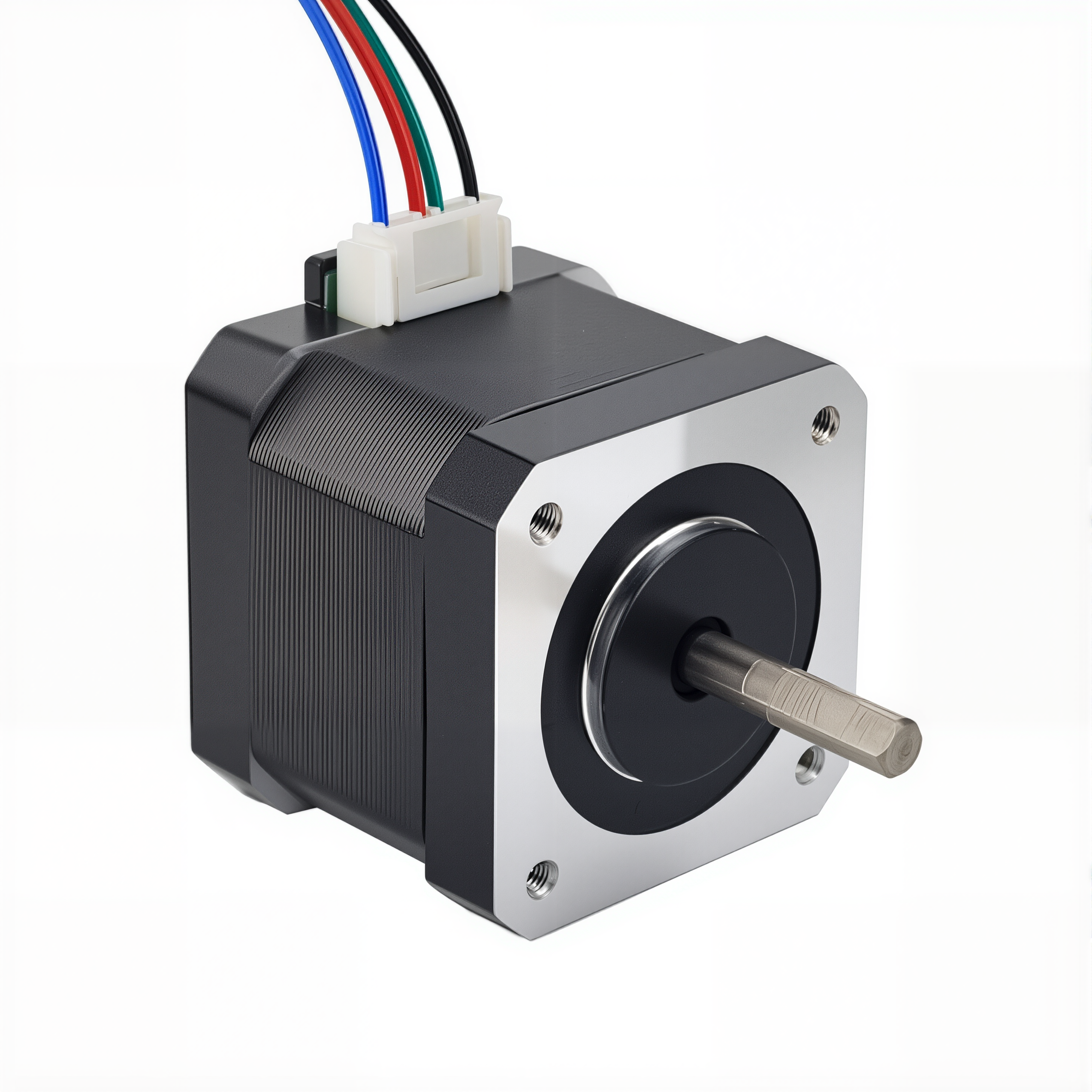

At first glance, NEMA 17 stepper motors may not look like much, but they are the unsung heroes behind countless machines, powering everything from 3D printers and robotics to home automation gadgets and DIY projects. These compact motors are renowned for their ability to move with precision, maintain their position firmly and perform repeated actions consistently without missing a beat.

Thinking of building a machine that requires controlled motion, but not sure which motor to choose? You’re not alone. With so many different sizes, specifications, and types of wiring, it's easy to feel overwhelmed before you even start assembling.

That’s where understanding the NEMA 17 category can be really helpful. It is one of the most commonly used stepper motors, particularly in maker communities and small-scale automation, and strikes a great balance between size, strength and versatility. Whether you're a beginner or an experienced builder, understanding how these motors work and how to select the right one can save you time and frustration, as well as preventing you from burning out components.

In this friendly, easy-to-follow guide, you’ll learn what NEMA 17 really means, discover the situations in which it performs best and receive practical advice on selecting the right model for your project. By the end, you will have the clarity and confidence to make smart choices and get your build moving — literally!

Understanding the Basics of NEMA 17 Stepper Motors

If you're new to the world of stepper motors, chances are you've already come across the term 'NEMA 17'. It’s a name that shows up all over build guides, electronics forums, and spec sheets. But what does it really mean? More importantly, what makes it so popular among makers and professionals? In this section, we’ll cover everything you need to know, without any unnecessary information, so you can feel confident working with this reliable little workhorse.

So, what does 'NEMA 17' actually mean?

Let’s start with the name. NEMA stands for the National Electrical Manufacturers Association, an organisation that standardises various electrical components in North America. The '17' in NEMA 17 simply refers to the size of the motor's faceplate — in this case, it is approximately 1.7 inches or 43.2 mm square.

This naming system is purely about physical dimensions, not the motor’s power, torque or performance. You could have two NEMA 17 motors side by side that look nearly identical, but one might produce significantly more torque or handle different voltage levels to the other.

One of the biggest misconceptions is that a bigger number means a stronger motor. That’s not always the case. The '17' only tells you the outer size of the frame, not what’s going on inside. Think of it like shoe sizes – just because two people wear size 10 shoes doesn't mean they can both run a marathon!

Core features and general specifications

Frame dimensions and mounting footprint

A NEMA 17 motor has a frame measuring 43.2 mm x 43.2 mm with standard mounting holes spaced evenly apart for straightforward integration into various designs. This size is ideal—it's big enough to provide decent torque, yet still compact enough to fit into tight spaces, such as 3D printer gantries or small robotic arms.

Typical shaft types and lengths

Most NEMA 17 motors have a round or D-shaped shaft, typically measuring 5 mm in diameter and 20–26 mm in length. Some have dual shafts for encoder attachments or external couplings. Just make sure the shaft type matches your gear or pulley system before buying.

Voltage and current ranges

These motors typically operate within a voltage range of 2–12 V and draw a current ranging from 1 A to 2.5 A per phase, depending on the model. However, the voltage itself doesn’t always reflect how much power the motor will deliver; that depends more on the driver used and how it regulates current.

Holding torque range and what it tells you

NEMA 17 motors offer a holding torque of between 26 and 84 oz-in (or roughly 0.18 and 0.59 Nm). This figure indicates the amount of resistance that the motor provides when holding a position without moving. Higher torque is useful for tasks involving heavier loads or requiring fine holding accuracy, such as pausing a 3D printer mid-layer or keeping a robotic arm locked in place.

How it moves: Inside the Stepper Motor

Step-by-step rotation: what makes it different from regular motors?

Unlike traditional motors, which spin continuously, stepper motors move in precise, incremental steps. Each electrical pulse moves the motor shaft by a set angle — typically 1.8° for NEMA 17s. This allows for exact positioning without the need for external sensors or encoders.

Two-phase hybrid technology and bipolar/unipolar wiring basics

Most NEMA 17 motors are two-phase hybrid steppers, meaning they combine the features of permanent magnet and variable reluctance motors to achieve greater precision. There are two main wiring setups:

- Bipolar (4-wire): Offers higher torque and efficiency, but requires a more sophisticated driver.

- Unipolar (5- or 6-wire): Easier to control, but generally provides lower torque.

If performance is your priority, as with a 3D printer or CNC setup, bipolar is usually the better option.

Microstepping: what it is and why it’s helpful for precision

Microstepping is a method of controlling a stepper motor by tiny fractions of a full step — think 0.9°, 0.45°, or even smaller. This smooths out movement, reduces vibration and makes the motor appear more precise, which is hugely beneficial for applications like 3D printing, where quality and detail matter. Bear in mind, however, that microstepping may reduce torque slightly, so there’s always a trade-off.

In short, NEMA 17 stepper motors are reliable, compact and versatile. Once you understand that 'NEMA 17' describes size, not power, and familiarise yourself with how these motors operate internally, you're well on your way to integrating them into smart, smooth-moving designs. Whether you’re building your first desktop CNC machine or fine-tuning a printer bed, understanding the basics will help you to make better, more informed choices right from the outset.

Where NEMA 17 Motors Shine: Use Cases and Applications

In the previous section, we covered the fundamentals of how a NEMA 17 motor works — its name, its internal structure, and the technical features that determine its performance. You now know that 'NEMA 17' refers to its size, not its strength, and that its performance in real-world scenarios is shaped by its torque, wiring type, and microstepping capabilities. Now, let's explore these features in more detail. This next section explores where NEMA 17 motors are used and why they have become a popular choice in so many industries and maker projects.

A favourite in 3D printing and CNC machines

If you have ever taken apart a 3D printer, or watched one build a model layer by layer, you will likely have seen NEMA 17 motors in action. They are a standard component in hobbyist and even semi-professional 3D printers, driving the X, Y and Z axes, as well as the extruder gear that feeds filament. But why are they so commonly used in this area?

Well, for one thing, they strike the right balance between size and strength. They’re compact enough to fit into small frames without crowding the machine, yet they're still strong enough to handle repetitive movement and holding torque with precision. They don't overheat easily and maintain a consistent grip — both critical qualities when printing detailed layers that require accuracy to within fractions of a millimetre.

These motors also excel at smooth transitions. Thanks to microstepping support, NEMA 17s can provide smooth motion without jittering, even at slower speeds. This is exactly what you need to avoid those tell-tale ridges or surface flaws in a finished 3D print. The same goes for CNC routers or engravers, where sharp turns and pauses need to be crisp and consistent.

On top of that, NEMA 17s are ideal for DIYers. They're affordable and widely available, and they're compatible with most open-source hardware and drivers. This makes them the obvious first choice for makers building their own machines at home.

They are ideal for robotics and automation projects.

NEMA 17 motors aren’t just for machines that carve or print — they’re also incredibly useful in robotics and small-scale automation projects. Thanks to their modest size and relatively strong torque, they are a smart fit for applications where controlled movement matters more than raw power.

Picture a small robotic arm carefully sorting parts on an assembly line or a gripper that needs to rotate smoothly to pick up an object. That’s where NEMA 17 comes in. Their precise stepping and position control enable movements that feel more human and less mechanical. Whether the task is rotating, lifting or sliding, this motor can handle it without the need for complex feedback systems.

They are also commonly used in linear actuators, robotic sliders and camera pan/tilt heads, where steady, predictable motion is essential. These are setups where repeatability matters — you need to be able to rely on your mechanism returning to the same position every time without drifting or skipping.

Because speed and torque often trade off in motor design, NEMA 17 motors strike a comfortable balance. They’re fast enough for responsive motion, but not so fast that they lose control. This makes them ideal for automation systems where precise timing and positioning are essential, but bulky servo motors are impractical.

They are also found in unusual or everyday devices.

While their most popular uses are fairly well known, NEMA 17 motors also appear in unexpected places. Have you ever seen a motorised camera slider used for time-lapse photography? Or a smart hydroponics system that adjusts lighting angles or nutrient flow? NEMA 17 motors are often behind those clever, compact movements.

One reason they appear in so many places is their ability to perform well in tight spaces. In small pumps or valves, for instance, they can precisely and repeatably control fluid flow. In medical devices, they facilitate the movement of components that require steady, silent and safe motion, such as adjustable beds, sample handlers or fluid dispensers.

Then there’s home automation. Whether it's opening blinds, adjusting a solar panel or controlling a hidden door panel — yes, even the secret bookshelf kind! — NEMA 17 motors offer the perfect balance of control and flexibility for custom setups. Many of these systems are built by hobbyists or prototypers, so the availability of NEMA 17-compatible hardware and documentation is a huge plus.

Lastly, we cannot overlook the role they play in STEM education and DIY electronics. Schools and universities use NEMA 17s in robotics kits, engineering labs and learning platforms because they are reliable, affordable and safe for beginners to use. And what about curious minds at home? They open up a world of possibilities.

In short, the NEMA 17 isn’t just a tool for one job: it’s a versatile performer that can adapt to a wide range of creative and technical needs. Whether you’re working on a complex project or a fun weekend hobby, this motor is a valuable addition to your parts list. Now that you know where and how it’s being used, you can see why it has earned such a strong reputation across industries and communities alike.

Choosing the Right NEMA 17 for Your Project

So far, we've explored what a NEMA 17 motor is and its common uses, from 3D printers and CNC machines to smart home devices and robotics. Its balance of size, precision and reliability makes it a popular choice for many applications. However, as you might have guessed, not all NEMA 17 motors are created equal. While they share a common frame size, their specifications can vary widely. Therefore, selecting the right NEMA 17 for your build requires more than just grabbing the first one you see online; it involves matching its performance to your specific needs.

Let's take a closer look at the key considerations that will help you make a smart, confident choice.

Important performance considerations:

Torque and speed trade-offs: what you need to know

Torque and speed have an inverse relationship — when one increases, the other often decreases. This is particularly true of stepper motors like the NEMA 17. If your project requires high torque for tasks such as lifting a platform or moving a heavy part, you will probably need to accept slower movement speeds. Conversely, if your goal is rapid motion with light loads (such as spinning a camera gimbal), a motor with lower torque but higher speed will probably suffice.

The key is to consider what your motor is actually doing. Will it hold something in place for long periods? Or will it move something quickly and repeatedly? Clarifying this will help you avoid buying a motor that’s either overpowered and wastes energy, or underpowered and causes missed steps or overheating.

Voltage and driver compatibility

NEMA 17 motors can operate across a range of voltages, but not every motor will be compatible with every power supply or stepper driver. Most models are rated between 2 V and 12 V, with current ratings from 1 A to 2.5 A per phase. These numbers are critical, especially when pairing your motor with a driver. A mismatch could lead to performance issues or even damage the components.

Before purchasing, check your driver’s specifications to see what voltage and current it can safely handle. Some setups, particularly those in 3D printers, use current-limited drivers, so it is essential to know how to match the motor’s coil resistance and amperage to the driver in order to ensure stable performance.

Consider load weight, movement speed and positioning accuracy.

Let's break it down. If your project involves heavier loads, you’ll need a motor with a higher holding torque. For applications that require quick stops and starts, such as pick-and-place mechanisms, consider acceleration ratings and rotor inertia. If you need to reach a specific location every time, such as a sliding platform that must stop within 0.1 mm, focus on step angle and consider using microstepping for smoother control.

There's a lot to consider, but don't worry — you don't need to be an engineer. Just make a list of your project’s physical demands and you’ll already be ahead of most people who are shopping blindly.

Wiring and control options

Bipolar vs. unipolar wiring: differences and common setups

NEMA 17 motors usually come in bipolar (4-wire) or unipolar (5- or 6-wire) configurations. Bipolar motors offer more torque and efficiency, making them ideal for most modern applications, particularly in CNC or 3D printer builds. Unipolar motors are simpler to control, but they sacrifice some torque.

If you’re using a standard driver such as the A4988 or TMC2208, you will almost certainly be using a bipolar stepper motor. Therefore, before wiring anything up, ensure you are clear on the type of motor you have, as this affects not only the wiring, but also how your controller interprets step and direction signals.

Stepper drivers: what they do and how to pair them with your motor

A stepper driver controls the current and timing going to your motor’s coils. It translates signals from your microcontroller or control board into precise electrical pulses that tell the motor when and how to move. Different drivers have different current limits, microstepping capabilities and thermal protections.

It is essential to pair your NEMA 17 with the right driver. For example, if your motor is rated at 1.7 A per phase, you will need a driver that can safely provide this amount of current without skipping steps or overheating. Popular options include the DRV8825 and TMC2209, which are flexible, quiet and easy to configure.

Here are some basic tips on setting current limits and tuning movement.

To maximise the performance of your NEMA 17 motor, take a few minutes to adjust the current limit on your driver. Set it too high and you risk burning out your motor. Set it too low and it may skip steps under load. Many drivers come with a potentiometer for fine-tuning – just make sure to refer to the datasheet and use a multimeter if needed.

Also consider tuning the acceleration and speed settings in your software. Slower acceleration ramps may seem unnecessary, but they help to prevent stalling, especially when working with heavier loads or sudden direction changes.

Helpful questions to ask before you buy:

What is the purpose of your build, and how critical is precision?

Start here. Is this a casual weekend project or a tool you’ll rely on daily? If precision and repeatability are non-negotiable, prioritise motors with low step angles, high torque and solid construction. If you’re experimenting or just learning, a general-purpose NEMA 17 motor will probably meet your needs.

How much torque do you really need?

While it’s tempting to go big “just in case”, remember that more torque often means more weight, current and heat. Try to calculate your required torque using load values, or look at similar projects online. Many suppliers also provide torque curves showing performance at different speeds, which can be extremely helpful when making a decision.

Will it fit your space and mounting requirements?

Don’t forget the basics! Always check the mounting hole spacing, shaft diameter and motor length before placing an order. Some NEMA 17 motors are longer or have double shafts, which can affect how you mount them in tight enclosures. Taking a quick measurement upfront can save you a lot of rework later.

When you match your project requirements to the right specifications, choosing a NEMA 17 becomes much less overwhelming and much more rewarding. The right motor can breathe life into your entire design, delivering smooth, accurate motion that feels like magic. And it's always good to take a moment to appreciate the engineering behind something that just works.

Conclusion:

By now, you have a solid understanding of what makes the NEMA 17 stepper motor such a reliable and popular choice. We broke down what 'NEMA 17' actually means, explored its core features and examined how it works. We also talked you through its most common real-world applications, from 3D printing and CNC machines to robotics and smart devices, and showed you how to choose the right motor based on performance, wiring and your project's specific needs.

If you’ve been unsure about where to start or what to look for in a stepper motor, this guide should provide the clarity and confidence you need to move forward. Apply what you have learnt here to your build, whether that involves sketching out your wiring plan, comparing torque ratings or testing different drivers.

The next step is yours. Keep learning, keep building, and don’t be afraid to experiment. NEMA 17 motors are dependable and beginner-friendly, and with a little hands-on experience, you'll see just how powerful and precise they are at bringing your ideas to life.

You can do it — happy building!